As time goes by, R&D technology is continuously improved, and various products are also getting through constantly promotion in performance, materials, packaging and production technology. Since limited protective performance and high weight have long been a great barrier on the way to the innovation of bulletproof products, scientists and researchers in the field of bullet-proof protection have been focusing on the search and development of new materials, and the improvement and enhancement of the original materials, for many years. The super PE is just one of the new improved materials with high-performance.

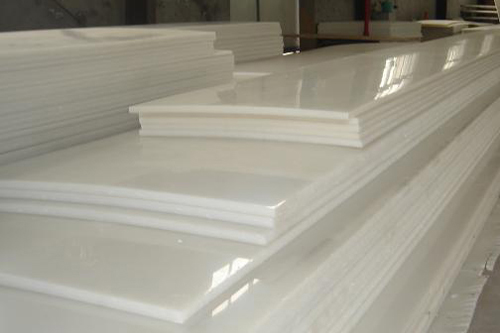

Ultra-strong thin film with a high modulus is made of a special type of UHMWPE (Ultra High Molecular Weight Polyethylene), and it is the strongest UHMWPE available in the world. Super PE is the upgrade of UHMWPE, so beside all the characteristics of UHMWPE itself, it also processes other great properties that UHMWPE does not have. For example, weight to weight, the super PE gets 11 times the strength of steel, and it also has higher modulus and better abrasion resistance, UV resistance, creep properties and thermal-aging performance than common UHMWPE fibers. The excellent properties of super PE derive from its special technic and manufacturing process. Generally, the manufacture of super PE mainly includes several steps: 1) A quantity of UHMWPE powder is compacted into a sheet; 2) This sheet is then rolled and stretched until it reaches the right thickness(between 50 and 60 µm). By this process, the long polymer chains of the UHMWPE are aligned, giving super PE its high mechanical properties and the result is the film TA23 (133mm); 3) To make the UD laminate, films are laid next to each other to form a laminate with a maximum width of 1.6 m.

Another option is to slit the film to create narrow films; 4) The UD brick laminate is cross-plied to create super PE cross-ply. Intensive quality control completes the manufacturing process of super PE. Bulletproof products made of super PE all have a very high energy absorption capability, giving them a remarkably high stopping power for bullets and fragments. Therefore, it has been already got a wide application in bulletproof industry.

In addition, super PE has also been applied to many fields:

Fabrics and composites

Super PE lends itself also for making fabrics. These fabrics can be used in composites where

the impact resistance of super PE will improve the properties of carbon and glass based

composites.

Ropes, nets and cables

the film shape super PE is intrinsically more durable than any UHMWPE fiber, and it also has good abrasion resistance. All these make it ideal for making ropes, nets and cables

In addition, super PE can also be used in the manufacture of air containers, sails and so on. In a word, super PE can be used in all products with strict requirements in strength and weight.

If there are still some questions, welcome to contact us.

Newtech has been long dedicated to the development and research of bulletproof equipment, we provide quality NIJ III PE Hard Armor Plates and NIJ IIIA vests, as well as many other products. When considering the purchase of hard armor plates, you can visit the website of Newtech to find the best one for yourself.